Description

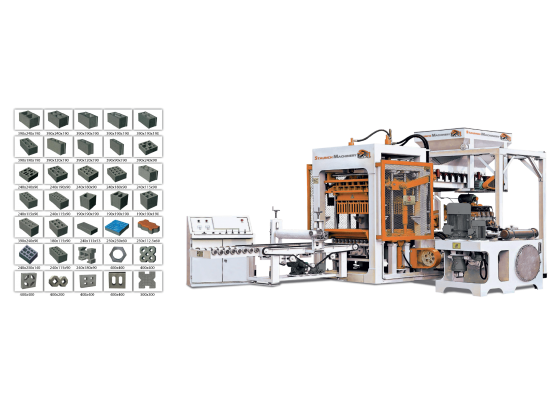

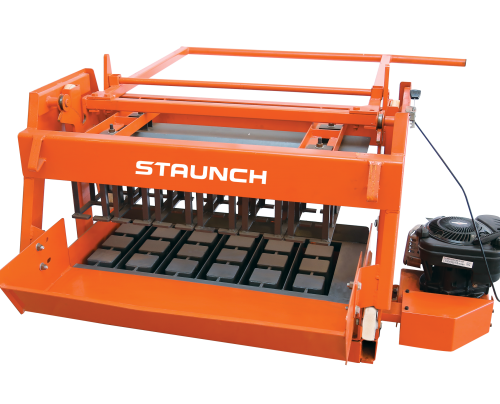

STAUNCH Semi-Automatic Block Production Line

Semi-Automatic Block Production Line

About the SABPL 1360

1. The SABPL 1360 is equipped with a high-density steel chassis. The chassis is assembled via a special craft welding for extra strength.

2. The mold axels of the press are made of chromium-plated high-grade steel.

3. The driving force mechanism is accurately designed to drive the mold on its axels in complete symmetry. This accuracy minimizes the height difference in the pallet and maintains consistency in the production line.

4. The SABPL 1360 adopts hydraulic pressure/sensor technology in discharging the mix. The latter cutting-edge technology allows the centrifugal discharge of the mix guarantying an even distribution.

5. The SABPL 1360 is equipped with a computer-controlled hydro-electric vibration mechanism. The latter technology allows the adjustment of the vibration frequency up to 17.5 G.

6. The SABPL 1360 is equipped with the main control panel. The panel is user friendly and backed by 15 years of research & development.

Technical Data

| Production/ hour | Production/ 8hour | Production/300days | ||

| Number of blocks per pallet | ||||

| Blocks 390x190x190 | 8 | 1, 360 | 15, 360 | 9, 216, 000 |

| Multi Cellular Bricks 240x115x90 | 18 | 4,320 | 34, 560 | 20, 736, 000 |

| Paving Bricks 225×112.5×60 | 18 | 4,320 | 34, 560 | 20, 736, 000 |

| Standard Bricks 240x115x53 | 36 | 8, 640 | 69, 120 | 41, 472, 000 |

| Semi-Automatic Block Production Line | |

| Overall dimensions (mm) | 4290x2150x2750mm |

| Pallet size (mm) | 850x850x20mm |

| 850x850x10mm | |

| Machine weight (Kg) | 11500Kg |

| Vibration frequency (Hz) | 50_70Hz |

| Cycles (s) | |

| Power requirement (kW) | 3205Kw |